Aerospace Structures

- Intro to Structural Analysis

- Stress

- Shear and Normal stress produce fundamentally different forces in the material

- What is strain? What are the units of strain?

- What is normal strain? What is shear strain?

- What is a positive and negative normal strain?

- What is a positive and negative shear strain?

- Normal Strain is?

- Shear Strain is?

- Poisson’s ratio?

- Hooke’s Law?

- Plane (2D) Problems

- Beams and Plates

- 2D State of Stress

- Aircraft Materials

- Static Equivalence

- Partial Derivative

- Support Conditions

- Internal Loads

- Force and Moment Diagrams

- Euler Buckling

- Inelastic Buckling

- Plate and Local Buckling

- Bending

- Thin Wall Assumptions

- Shear

Intro to Structural Analysis

Content Tags: Hookes Law, Internal Loads, Strain, Stress, Supports Created: March 6, 2022 9:10 AM

Stress

- Stress on a small element of a material under load

- 2 types of stresses:

- Normal

- Shear

- Ask what does a load do to a cross section?

- What loads are there? Moments? Stresses?

Shear and Normal stress produce fundamentally different forces in the material

- Normal is a compressive or stretching action

- Shear is considered as though it acts on a plane

What is strain? What are the units of strain?

- Strain is a change in material distortion under the effect of a stress

- The units are dimensionless (Change in Length/Length)

What is normal strain? What is shear strain?

- Normal strain acts through the cross section of the body to lengthen or contract it

- Shear strain creates torsion and warping

What is a positive and negative normal strain?

- Positive normal acts in torsion

- Negative acts to compress

What is a positive and negative shear strain?

- Positive and negative only alters the direction of the torsion. So clockwise or counter-clockwise

Normal Strain is?

- The slope of displacement

Shear Strain is?

- Still non-dimensional

- Relationship??

Poisson’s ratio?

- Ratio of strains. Reaction strain acting in orthogonal direction is cause by original strain.

Hooke’s Law?

- Constant Value = Stress/Strain, while elastic.

Plane (2D) Problems

- Disregard a particular aspect because nothing important is happening in the other access out of plane. This needs to be carefully evaluated.

Beams and Plates

- Take a beam and extrude it for plates

- Plates have a poisson effect that beams don’t have

2D State of Stress

- Your stresses are dependant on your coordinate system

- Can resolve state of stress into principal stress

- Use Moores circle

- A cylinder under normal tension will fracture vertically

- A cylinder under shear will fracture diagonally. Imagine the shear diagram deforming a square into a kite shape.

Aircraft Materials

- Common Materials:

- Metals (Most discussed)

- composites

- Sandwich

Static Equivalence

- Same forces and same moments

- Internal loads must be equivalent to the external load that is acting on the body.

- Internal reaction loads are equal and opposite. The internal loads are not.

Partial Derivative

- The partial derivative is the derivative of a function with respect to one variable only

- This gives the rate of change, or slope, of a function with respect to one variable

Support Conditions

- Import drawings for supports. (Roller, Fixed, Pin). Add degree of freedom info.

- Rollers always provide a force in the Y direction regardless of the sign of the force. Not in the X direction. Or vice versa depending on the unit system.

Internal Loads

- 4 Types of internal loads:

- Normal (N)

- Shear (V)

- Torsional (T)

- Bending (M)

Force and Moment Diagrams

- Take a slice and determine the shear force and moment at that point (This is important for this course)

Reference Material

(1A)_Intro_to_structural_analysis-1.pdf

Euler Buckling

Created: April 28, 2022 11:02 AM

Euler Column Theory

- Valid, within the limits of assumptions

- Based on a perfect stable section column

- The column is perfectly straight

- Load is applied at the section centroid

- Column material is homogenous

- Stresses are in the elastic range

- No local section instabilities (no twist or deformation)

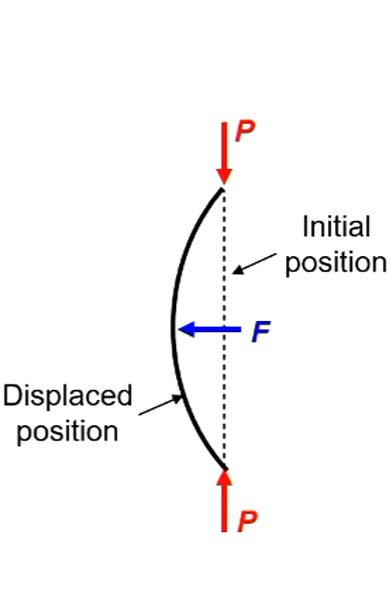

- Perfect column under compressive load P

- Load associated with buckling is $P_{CR}$

- If column is displaced by lateral load F

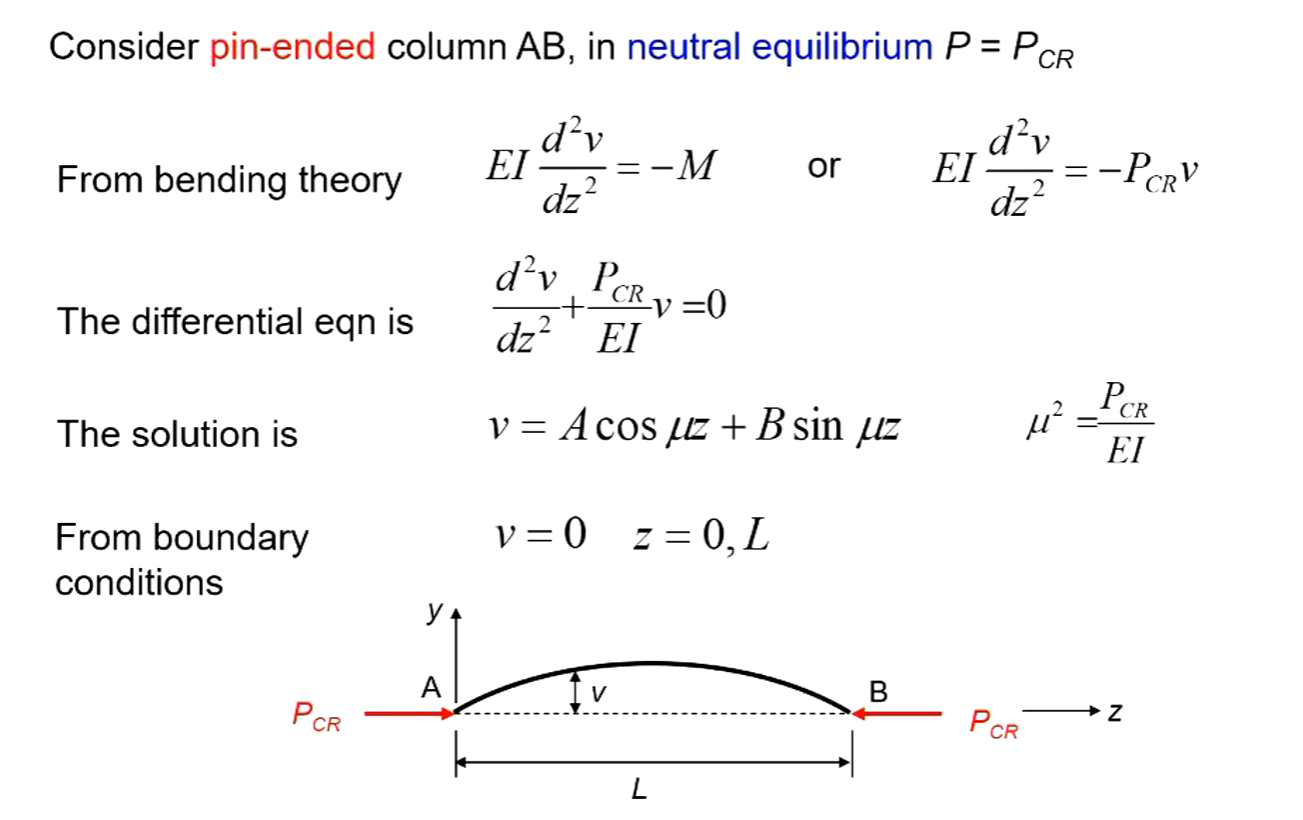

Derivation of Euler Buckling Equation

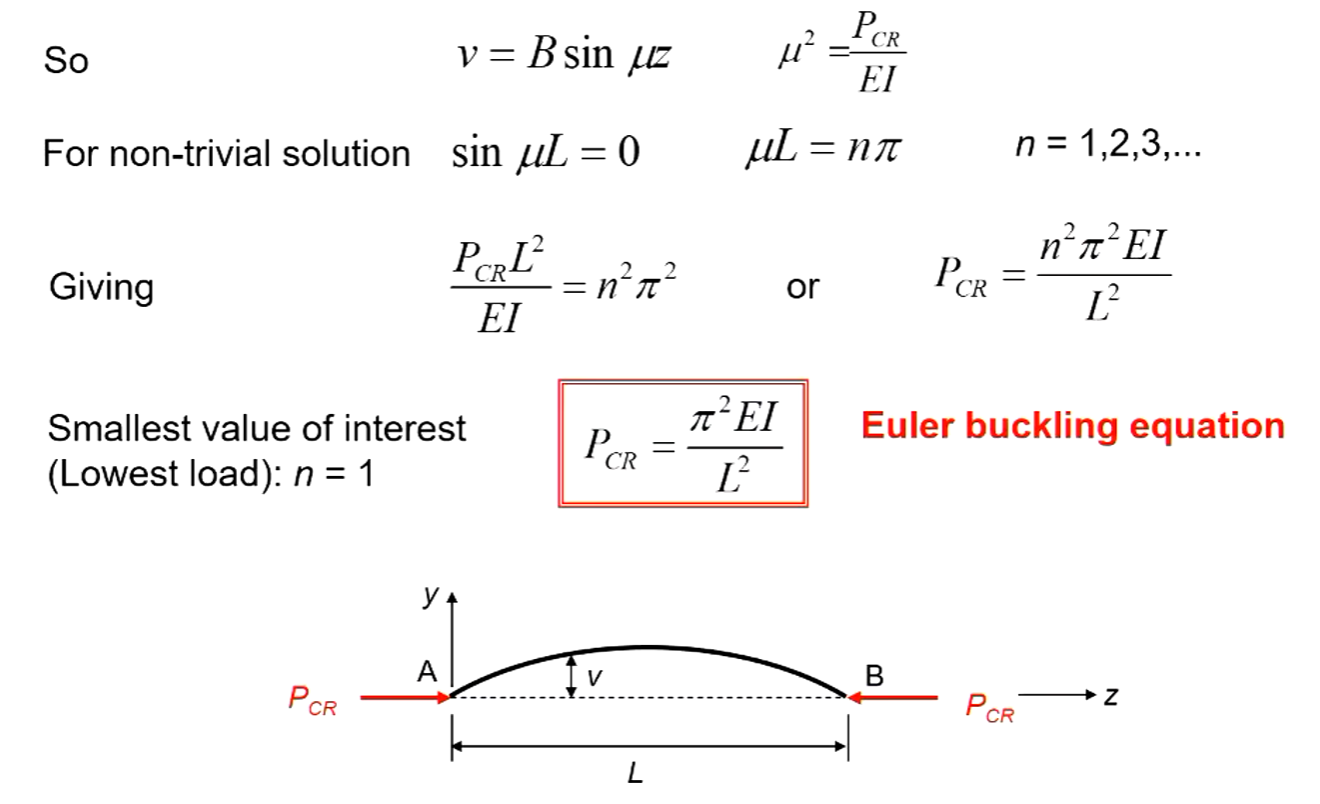

Buckling Modes

- Each n buckling mode (displacement shape) has an associated buckling load

- n = number of “half waves” in buckling mode shape

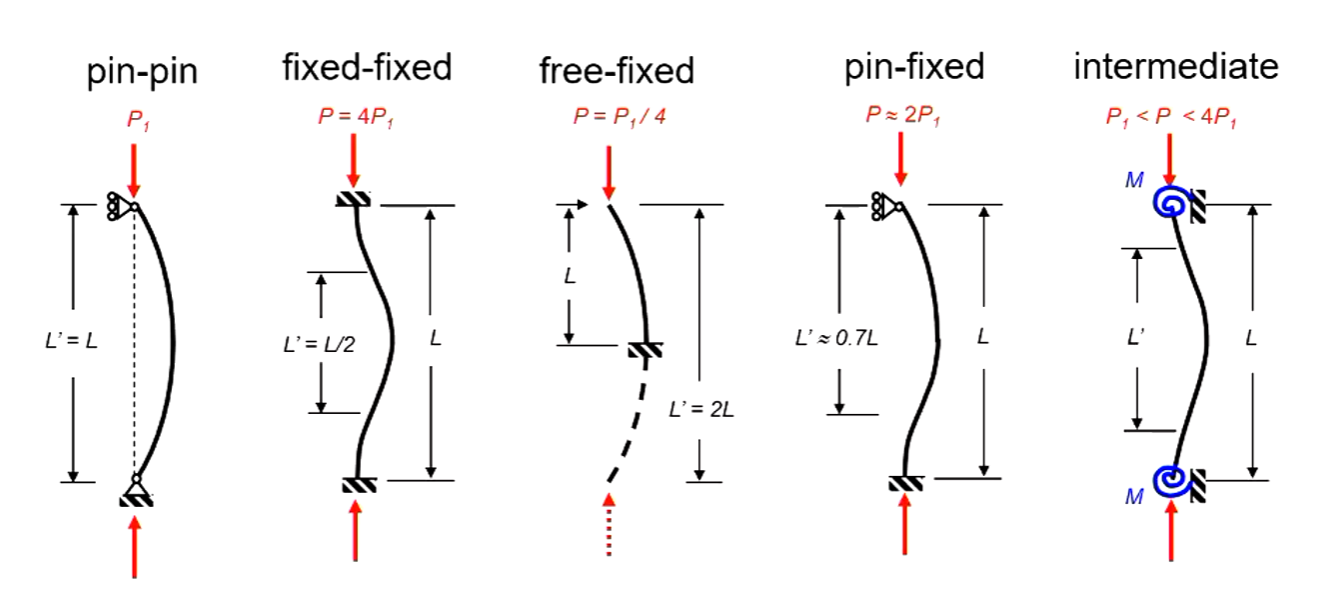

Effective Length

End Fixity

- How the ends of the columns are restrained

- Most columns have some form of restraint (end fixity)

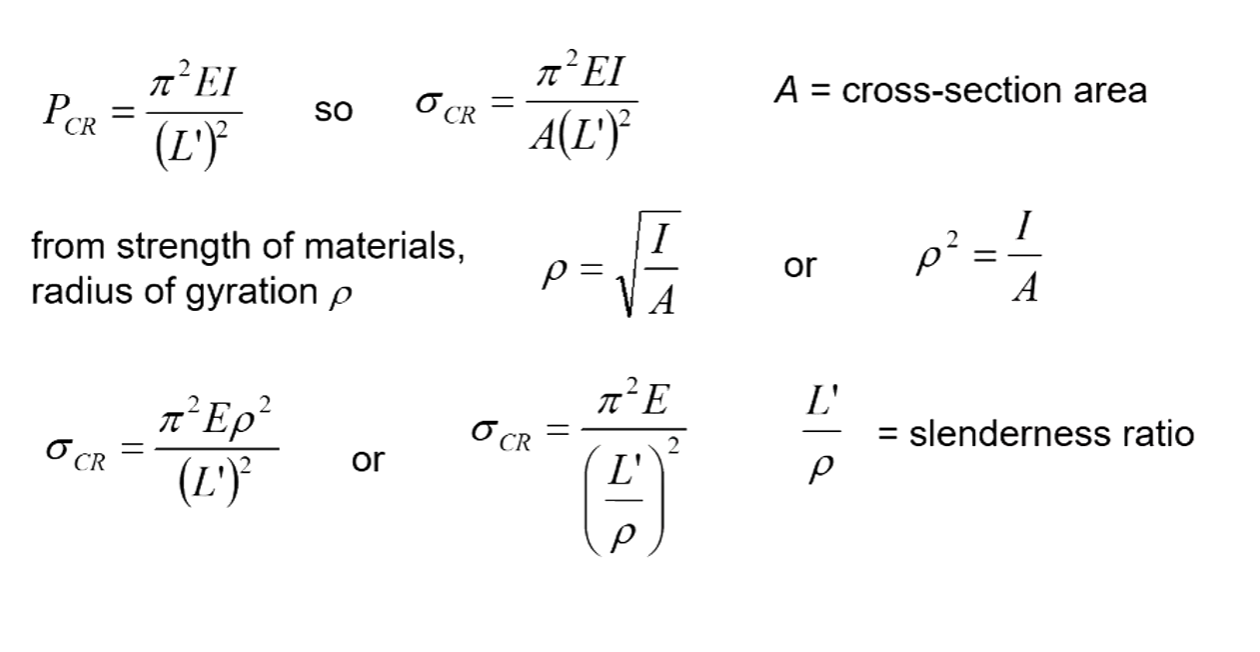

- To account for this, the effective length L’ is adopted $P_{CR} = {\pi^2EI\over (L’)^2}$

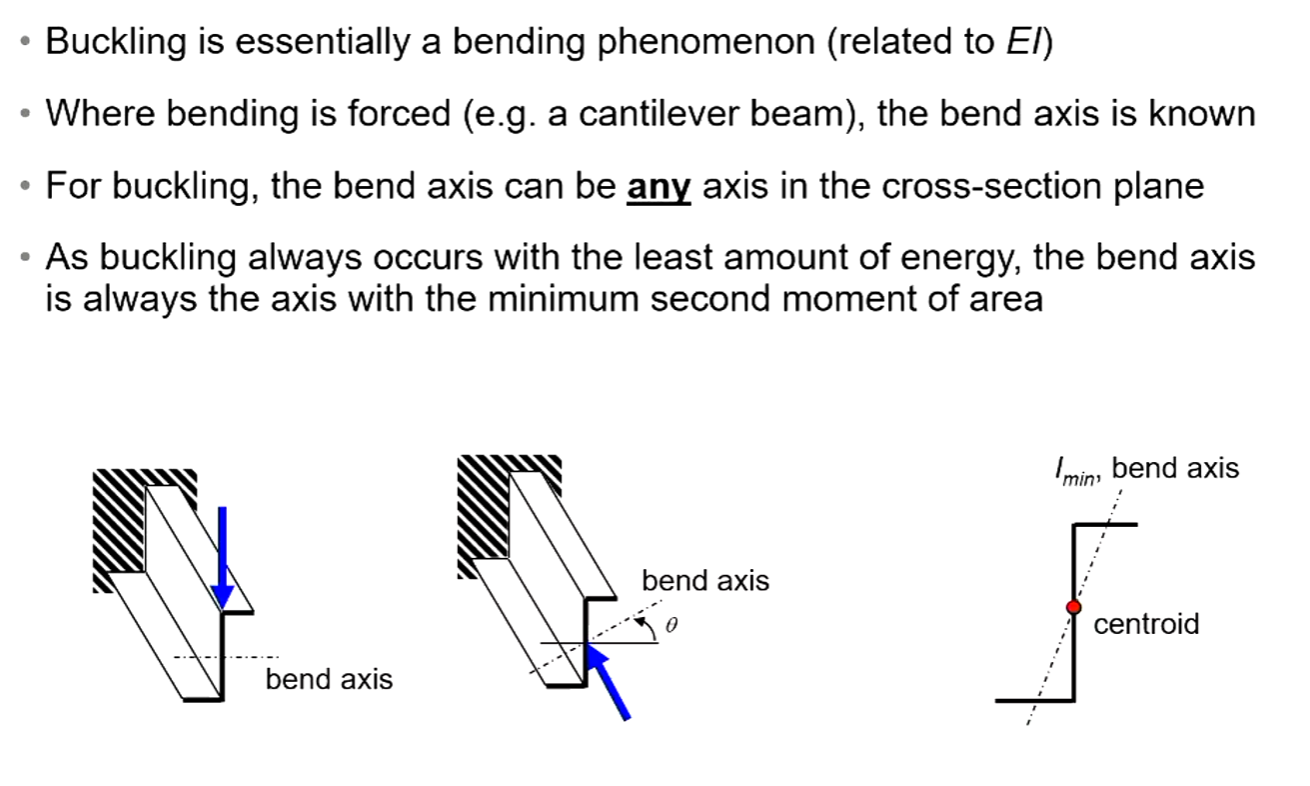

Second Moment of Area

- Buckling always occurs around the axis of $I_{min}$

Stress Form of Buckling Equation

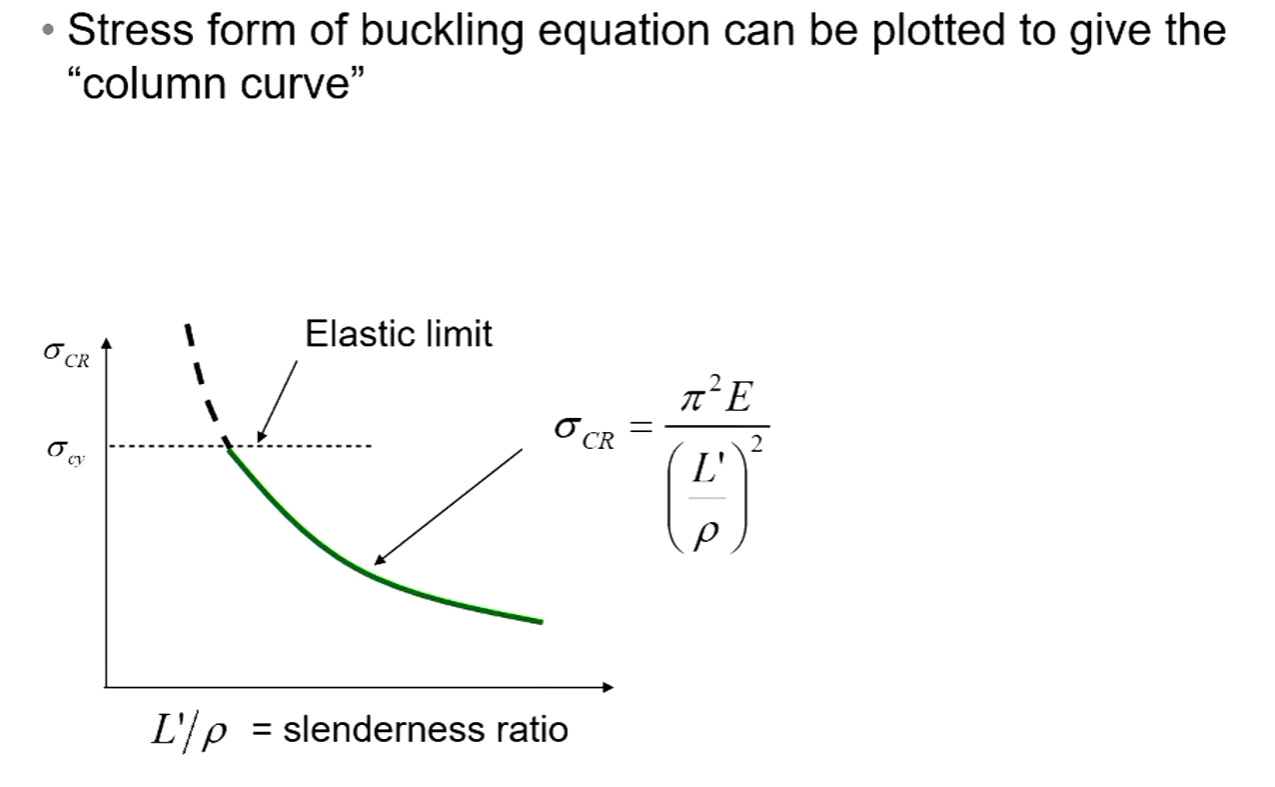

Column Curve

Inelastic Buckling

Column Curve Ranges

- Metal material behaviour is non-linear following yield or elastic limit

- “Long” columns buckle when material is still in elastic region

- “Short” columns undergo plasticity before buckling

- Euler theory will over-estimate the buckling stress in the case of a “short” column

- Very short columns (L’/$\rho$ ~ 10) fail by crushing, or “block compression”

Empirical Short Column Equations

- Empirical (test-based) relationships developed for buckling of thin-walled sections (which incorporates local buckling)

- Column curve is a structural response (not material)

- Empirical relationships developed for common sections and materials

- Linear and parabolic forms most common, other indices are possible.

- Linear:

- Parabolic:

- Stress $\sigma_{c0}$ is a property of the cross-section (assumed independent of length), and material

- Can be found using several approaches

- Assumed equal to ultimate compressive strength $\sigma_{cu}$

- Taken from test data for a very short column

- Determined analytically or semi-empirically

- Found using data sheets (e.g. ESDU), standards (e.g. MIL-HDBK), etc

Euler-Johnson Equation

- A type of parabolic short column equation

Inelastic Plate Buckling

- Elastic-plastic behaviour for metals affects buckling

- Similar behaviour previously seen for columns

- Buckling can occur at stresses above elastic limit

- Less common as requires thick plates

- One approach (less common in industry) treats the plate as a column

- Relate the plate to an equivalant column using:

- Then simply use the above inelastic equation depending on the situation (Linear, Parabolic, Euler-Johnson)

Plate and Local Buckling

Flexural Buckling

- Global Buckling

- Primary instability mode of the entire column, or instability due to overall column bending

- Characteristic length ~ distance between supports

- Primary instability mode of the entire column, or instability due to overall column bending

Rectangular Plates in Shear

- Buckling in shear is determined from the same equation

- Analytical derivation of buckling not considered here

- A rectangular plate in shear develops a series of closely space buckling waves at approximately 45 degrees

- The effect of boundary conditions and plate size is similar to that of a plate in compression.

- We use a different graph to obtain our K values but the process is the same from a calculation standpoint.

- In shear buckling the b in the equation is always the smaller dimension

- $\sigma_{cr} = {KE ({t \over b})^2}$

Rectangular Plates in Compression

- With plates we need to more carefully consider which mode of buckling will be take the least amount of energy.

- Across the width of the plate mode 1 is still the lowest so only one half wave will be present

- This is not true when considering the height.

- The plates will buckle into a shape that is the closest to maintaining “square” buckles along its length. So each buckle will occur at lengths that approximate square sections of the total plate.

- As seen above the plate buckles into two “square” sections. This is the lowest energy buckling mode.

- $K_{\infty}$ is a good approximate for really skinny plates.

Plate Buckling Stress

- Compression and shear stresses on a plate can lead to buckling

- Buckling load of a flat plate is dependant on

- Type of loading (compression, shear)

- Material (E, v, t)

- Edge support (fix, pin, etc)

- Geometry of the plate (dimensions, aspect ratio)

- Buckling stress of plates is always:

Where,

- K is a buckling constant

- Varies with restraint, geometry, loading, material

- E is elastic Modulus

- $({t\over b})$ is the ratio of the plate thickness to width.

- b is always the width of the loaded edge regardless of orientation for compression buckling

Local Buckling

- Occurs when the column acts like a collection of square plates. Common in thin-walled structures.

- Thin-wall panels can buckle before or after flexural buckling

- Usually confined to localised portions of the total length

- Characteristic length ~ cross-section dimensions

- Thin-wall columns see local buckling of the flanges

- Stiffened beams see skins buckling between stiffeners

- Simple predictions for local buckling can be made by analysing the structure as a series of plates

- The corners of a cross-section and the stiffeners in a stiffened beam provide restraint

- Each segment or plate has different geometry and boundary conditions and requires separate calculation

- The restraint applied on each plate by the corners and stiffeners is difficult to determine

- In both cases the restraint should vary between a fixed and simple support

- Simple support can be assumed for conservative estimates unless the condition is known or given

Bending

Bending Stresses

- Bending of a beam causes compression and tension stresses on a cross-section (bending stresses)

- These are direct stresses, normal to the cross-section

- Between the compression and tension regions is a line of zero bending stesses, called the neutral axis

- The neutral axis passes through the section centroids

- The neutral axis has no deformation or stains associated with bending stress

- Bending of a beam can occur around two axes

- The two in-plane axes of a cross-section

- bend axes, moment, stress distribution, resists all change

Symmetric Bending

- Symmetric Bending occurs for bending of beams with one or two axes of symmetry

- Axis of symmetry = “mirror plane”

- Bending behaviour is simplified as bending around the two axes acts independently

- Uses equation: $\sigma {bending} = {M{bending} \over I_x} y$

- For bending in two seperate axis we can calculate the stress for both and simply add them. Direct stress can also be added.

Asymmetric Bending Equation

- Bending always relates to a centroid coordinate system

- General equation for bending stress:

Works for any bending problem. Including symmetric bending and single moment bending.

Bending Sign Convention

Thin Wall Assumptions

Equations

| Equation | Explanation | Variables |

|---|---|---|

| $I_{x} = {bd^3\over 12}$ | Second Moment of Inertia for a rectangle, measured from the x axis. | d is the direction perpendicular to the y axis. |

| $I_{x} = {b^3d\over 12}$ | Second Moment of Inertia for a rectangle, measured from the y axis. | b is the direction perpendicular to the x axis. |

Properties of Plane sections

- First Moment of Area (important for centroids)

- Second Moment of Area

- Rotation of Axes

- Parallel axis theorem

Stiffened Structures

- Consist of two structural elements, which can be assumed to perform seperate functions.

Shear

Shear flow

- Force on Length

Where,

T = applied torque, Ae = area enclose by cross-section (mid-line)